Getting an Accurate Laser Cutting Quote: A Guide to Laser Cutting Cost Estimation

- Bridget Brooks

- Dec 15, 2025

- 4 min read

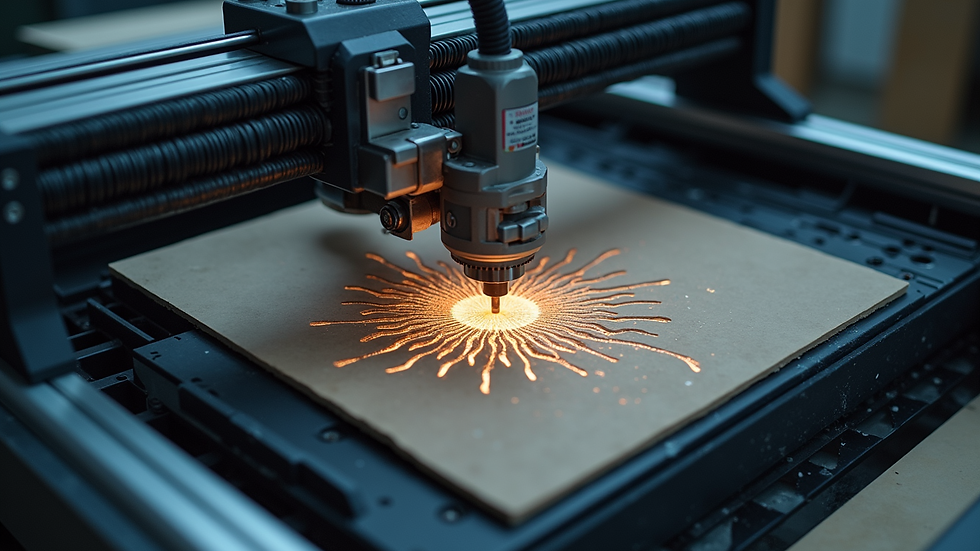

When planning to order bulk custom products, understanding how to get an accurate laser cutting quote is essential. The price depends on many factors, and knowing these can help you budget correctly and avoid surprises. This guide explains the key elements that affect laser cutting cost estimation and offers practical advice to get the best value.

Understanding Laser Cutting Cost Estimation

Laser cutting cost estimation involves calculating the total price based on material, design complexity, machine time, and finishing processes. Each factor contributes to the final cost, so it is important to consider them all.

Material Type and Thickness

The type of material you choose has a significant impact on cost. Metals like stainless steel or aluminum usually cost more to cut than wood or acrylic. Thickness also matters. Thicker materials require more power and time, increasing the price.

For example, cutting a 1/8 inch thick aluminum sheet will cost less than cutting a 1/4 inch thick sheet of the same size. Always specify the exact material and thickness when requesting a quote.

Design Complexity and Size

The complexity of your design affects the cutting time. Simple shapes with straight lines take less time than intricate patterns with curves and small details. Larger designs also require more machine time.

If your design has many small holes or tight corners, the laser must slow down to maintain precision. This increases the cost. Providing a clean, optimized design file can help reduce unnecessary cutting time.

Quantity and Batch Size

Ordering in bulk usually lowers the cost per piece. Laser cutting machines can run continuously, so producing many identical parts is more efficient. However, very small batches may have higher costs due to setup time.

Discuss your expected order size with the supplier. They may offer discounts for larger quantities or suggest batch sizes that optimize production.

Factors Influencing Laser Cutting Cost Estimation

Several additional factors influence the final price. Understanding these helps you prepare a detailed request and get an accurate estimate.

Machine Type and Technology

Different laser machines have varying power levels and capabilities. Fiber lasers are faster and more precise for metals, while CO2 lasers work well on wood and acrylic. Higher power machines may cost more to operate but can reduce cutting time.

Ask the supplier about the type of laser used and how it affects pricing. Some materials require specific lasers, which can influence cost.

Setup and Programming Time

Before cutting, the machine must be programmed with your design. Complex jobs require more setup time. If your design needs multiple passes or special engraving, this adds to the cost.

Providing a ready-to-use vector file in formats like DXF or AI can reduce programming time. Avoid raster images or low-resolution files.

Finishing and Post-Processing

Some projects need additional work after cutting, such as deburring, polishing, or painting. These services add to the total cost. Clarify if you want the supplier to handle finishing or if you will do it yourself.

Shipping and Delivery

If you order bulk products, shipping costs can be significant. Some suppliers include shipping in the quote, while others charge separately. Confirm delivery terms to avoid unexpected fees.

How to Prepare for a Laser Cutting Quote Request

To get an accurate laser cutting quote, prepare detailed information about your project. This helps the supplier provide a precise estimate and reduces back-and-forth communication.

Provide Clear Design Files

Submit vector files with clean lines and no overlapping shapes. Common formats include DXF, AI, or SVG. Avoid PDF or raster images unless the supplier accepts them.

Specify Material and Thickness

State the exact material type and thickness. If you are unsure, ask the supplier for recommendations based on your project needs.

Define Quantity and Dimensions

Include the number of pieces and the size of each part. If you want multiple designs in one batch, list them separately.

Mention Finishing Requirements

If you need deburring, painting, or other finishing, specify these clearly. This helps the supplier include all costs in the quote.

Ask About Lead Time

Bulk orders may take longer to complete. Ask the supplier about production and delivery times to plan accordingly.

Tips for Comparing Laser Cutting Quotes

When you receive multiple quotes, compare them carefully. Price is important, but so is quality and service.

Check what is included: Some quotes cover only cutting, others include finishing and shipping.

Look for hidden fees: Setup charges or minimum order fees can increase the total cost.

Ask about revisions: If your design changes, find out how it affects pricing.

Consider supplier experience: Established companies may offer better quality and reliability.

Request samples: If possible, get a sample cut to check quality before placing a large order.

Next Steps to Secure Your Laser Cutting Project

Once you understand the cost factors and have prepared your information, you can request a laser cutting quote from a trusted supplier. Clear communication and detailed specifications help ensure you get an accurate estimate and a smooth production process.

By following these guidelines, you can confidently plan your bulk custom product order and manage your budget effectively. Accurate laser cutting cost estimation is the first step toward a successful project.

If you want to move forward, gather your design files and material details. Contact your chosen supplier with all the necessary information. This approach saves time and helps you get the best price for your custom laser cutting needs.

Comments